Proof of concept on the digitalization of Falcon airplanes’ production line. Interactive interfaces and scenario of use.

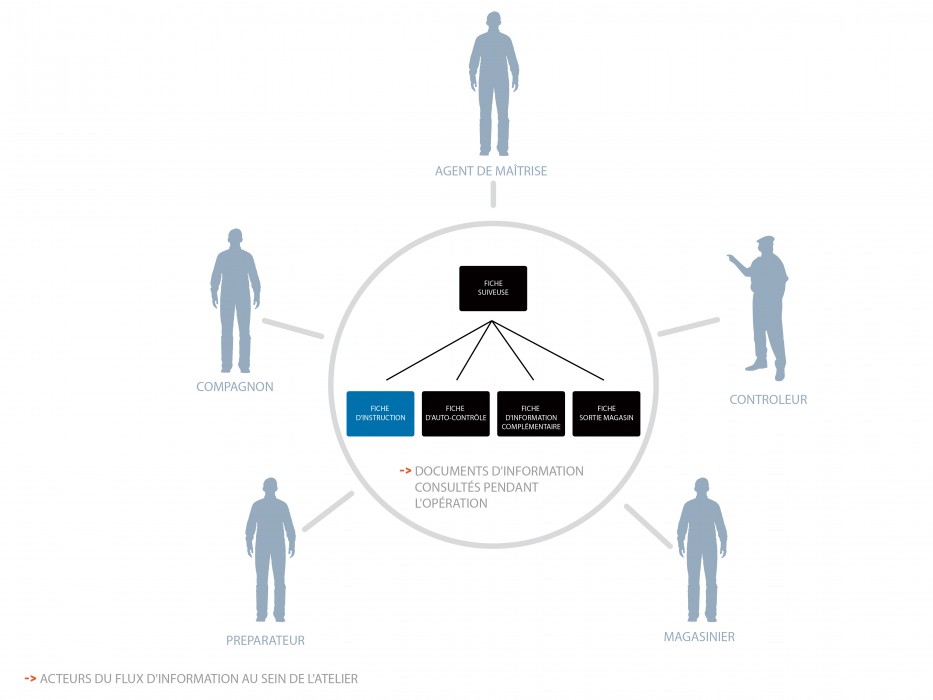

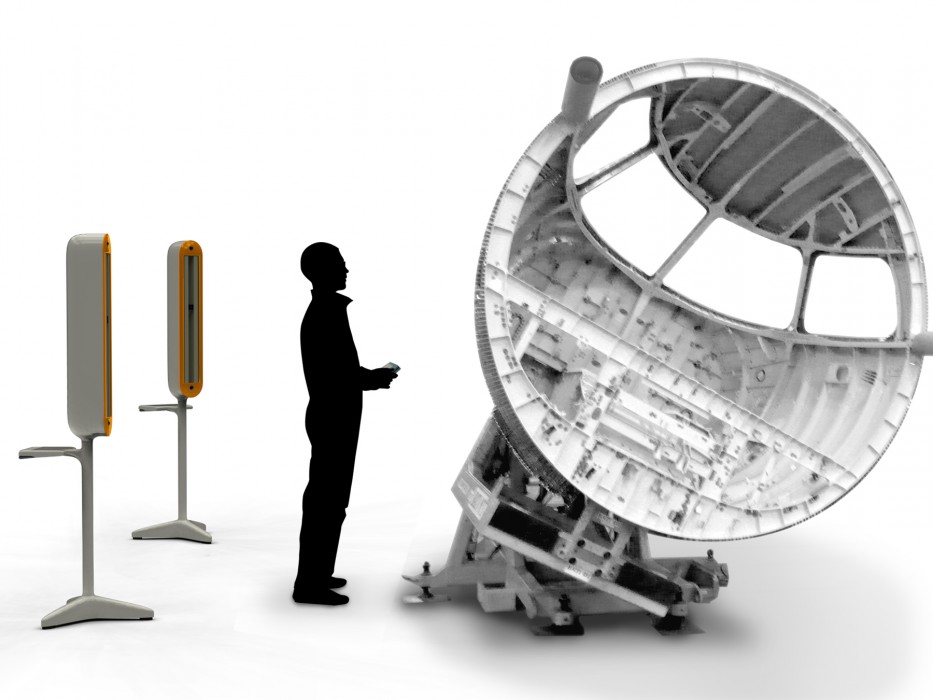

Dassault Aviation aims to integrate digital technologies (3D, rendering, augmented reality, geo-localization…) to the production line in its plant. The goal is to improve productivity, enhance the quality and traceability of the industrial operations and allow further flexibility to the production line (modification of cycles, evolution of rhythm…)

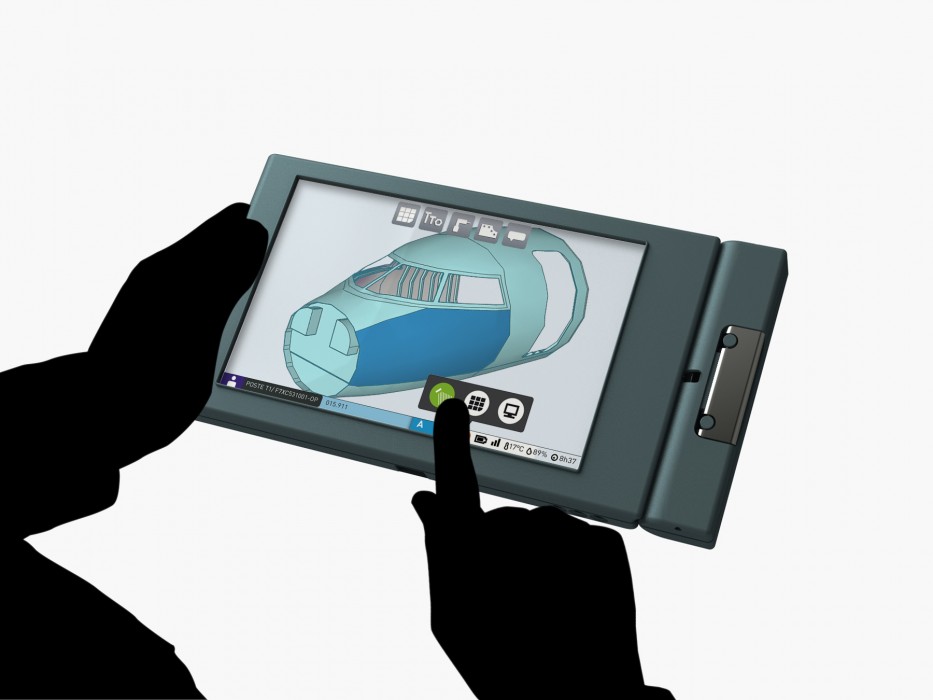

This research project integrates these technologies to the production line considering the operators’ practices, uses and existing tools, on a user-centered approach. We have designed a digital workspace integrating an interface tool that provides the operator access to the digital model, the information system, the management system and the control of the production line. These “smart” assembly stations allow the operators to participate more actively in the evolution of the process, enhancing the quality, productivity and flexibility by integrating the modifications and updates